The field of robotics is advancing at an incredible pace, with new technologies emerging that promise to reshape industries, enhance productivity, and change how we interact with machines. From AI to advanced sensors, these key robotics technologies are driving innovation and pushing the boundaries of what’s possible. Here are 10 key robotics technologies to watch in the coming years.

1. Artificial Intelligence (AI) and Machine Learning

AI is at the heart of many advancements in robotics. By enabling robots to learn from their environment and improve their performance over time, AI allows robots to make decisions autonomously, adapt to new tasks, and optimize their functions. Machine learning algorithms are continually enhancing robots’ ability to perform complex tasks with higher accuracy and efficiency, making them smarter and more capable in industries like healthcare, manufacturing, and logistics.

2. Autonomous Navigation and SLAM (Simultaneous Localization and Mapping)

Autonomous robots, such as delivery drones and warehouse robots, rely on SLAM technology to navigate and map their surroundings in real time. This technology allows robots to operate without human intervention, creating detailed maps of their environment while continuously updating their position. SLAM is crucial for applications like autonomous vehicles, drones, and mobile robots, enabling them to perform tasks in dynamic and unknown environments.

3. Robot Perception and Computer Vision

Robot perception, powered by computer vision technology, enables robots to see, understand, and interpret their surroundings. By using cameras, sensors, and AI algorithms, robots can recognize objects, identify obstacles, and understand visual cues. This technology is essential for applications in industries such as agriculture, logistics, and healthcare, where robots must interact with complex environments and perform intricate tasks.

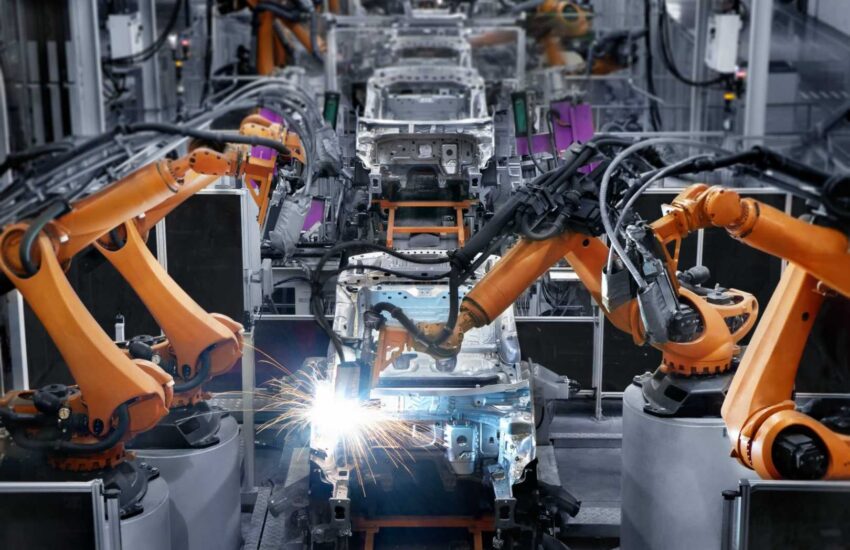

4. Collaborative Robots (Cobots)

Collaborative robots, or cobots, are robots designed to work alongside humans in shared environments. Unlike traditional robots that operate in isolation, cobots are equipped with advanced sensors and safety mechanisms that allow them to safely collaborate with human workers. Cobots are being adopted in industries such as manufacturing, healthcare, and logistics to enhance productivity, assist with repetitive tasks, and reduce the risk of injury.

5. Robotic Grippers and End-Effector Technologies

Robotic grippers and end-effectors are key components that allow robots to manipulate objects in their environment. With advancements in soft robotics and dexterous grippers, robots can now handle delicate items and perform tasks that require fine motor skills, such as sorting packages or performing surgery. These technologies are revolutionizing industries like e-commerce, manufacturing, and healthcare, where robots need to handle a variety of objects with precision.

6. Robotic Exoskeletons

Robotic exoskeletons are wearable devices that assist individuals with mobility impairments by augmenting their physical abilities. These exoskeletons can help users regain the ability to walk, lift heavy objects, and perform everyday tasks. In addition to improving the lives of individuals with disabilities, exoskeletons are also being used in industries like construction, logistics, and healthcare to reduce the risk of injury and enhance worker performance.

7. 3D Printing and Robotic Manufacturing

The integration of 3D printing and robotics is transforming manufacturing processes. Robotic 3D printers can create complex parts and products with high precision, significantly reducing waste and production time. This technology allows for the production of customized and intricate components that were previously difficult or impossible to create. By 2025, we can expect widespread adoption of this technology in industries like aerospace, automotive, and healthcare.

8. Soft Robotics

Soft robotics refers to robots made from flexible materials that mimic the movements and functions of natural organisms. These robots are highly adaptable and capable of performing tasks that rigid robots cannot, such as handling fragile objects or navigating narrow spaces. Soft robotics is gaining traction in industries such as agriculture, healthcare, and food processing, where robots need to interact delicately with objects or navigate complex environments.

9. Quantum Computing for Robotics

Quantum computing holds the potential to revolutionize robotics by providing immense processing power that can handle complex computations at unprecedented speeds. Although still in its early stages, quantum computing could significantly enhance robots’ ability to perform advanced simulations, optimize tasks, and solve problems that require massive amounts of data processing. This technology could enable robots to become even more autonomous, efficient, and intelligent.

10. 5G Connectivity for Real-Time Robotics

With the advent of 5G connectivity, robots can operate with faster, more reliable communication networks. 5G allows for the real-time transmission of large volumes of data, enabling robots to interact seamlessly with their environment and other systems. In industries like autonomous vehicles, remote surgery, and industrial automation, 5G will enable robots to perform tasks with minimal latency, improving efficiency and safety.

Also Read : 10 Groundbreaking Robotics Innovations

Conclusion

These 10 key robotics technologies represent the future of the industry, enabling robots to become smarter, more adaptable, and more capable across a range of applications. As AI, advanced sensors, and connectivity continue to evolve, robots will increasingly play a crucial role in shaping industries, improving human life, and transforming the way we live and work. Keeping an eye on these technologies will help us understand the future potential of robotics and its impact on society.